Efficiency and flexibility are the defining characteristics of an optimum working end. With controlled glass conditioning, you can streamline hot end performance, reducing operating costs and increasing the possibilities for glass forming.

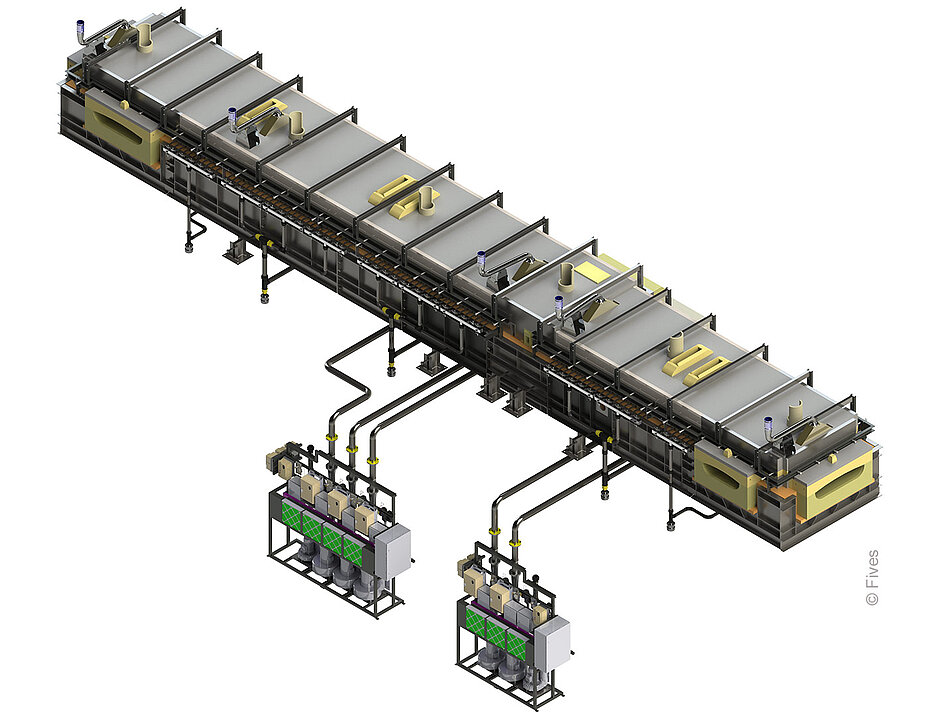

BH-F Working End technology

The BH-F Working End enables the glass conditioning process to start directly after the glass exits the throat riser, so you can deliver precise and stable glass entry conditions to each forehearth.

Simple and efficient system operation is at the heart of good performance. We transformed the delivery of molten glass from furnace to forehearth into a mathematically modelled process to enable optimum simplicity and efficiency.

By modelling glass flow pattern and its velocity against temperature control and hydraulic head loss, we've ensured the final BH-F Working End design provides a stable performance and the flexibility to meet the demands of modern glass production.

ADVANTAGES

Working end

- Improved thermal homogeneity

- Stabilised glass flow

- Better glass temperature stability

- Faster temperature response

- Production flexibility

- Simple operation

OPTIONS

Heating options

- Air-gas conversions

- Complete air-gas firing

- Valve and actuator control

- Variable speed fan control

- Radiant electric heating

- Direct electric heating

Cooling options

- Longitudinal centre-line

- High capacity longitudinal

- Radiation cooling exhausts

- Radiation cooling openings

- Mass heat extractor