Achieve optimum glass conditioning with our fuel-efficient systems: forehearths, working ends, feeder mechanisms and stirrers. With a focus on green solutions, our systems optimize heat transfer techniques, thereby reducing fuel consumption and emissions.

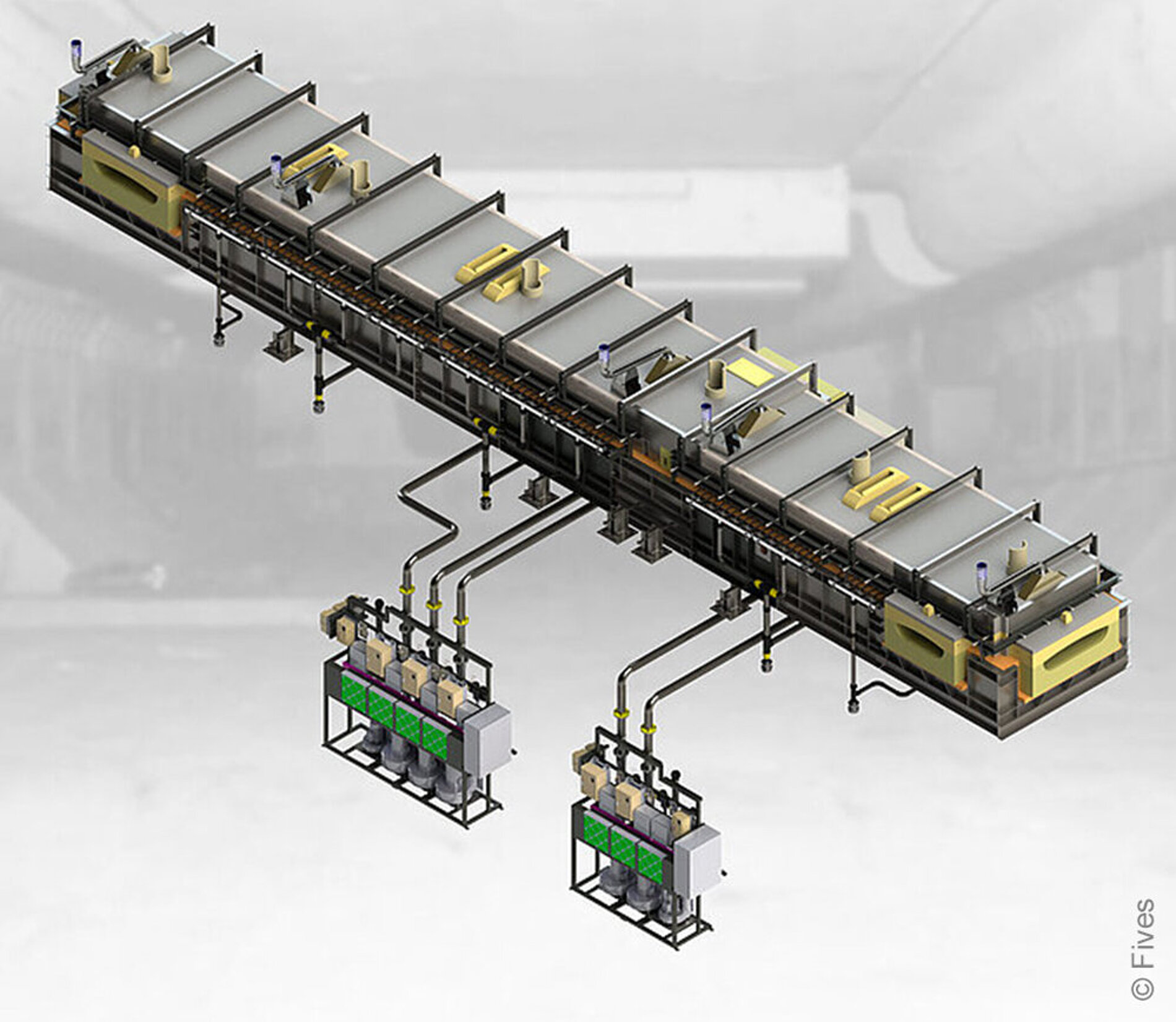

WORKING END

Efficiency and versality

Providing glass makers with flexible and readily controlled glass conditioning to streamline hot end performance, reducing operating costs and increasing the forming possibilities.

FOREHEARTH

Thermal homogeneity

Advanced design to meet the increasing demands on glass production for high capacity yields with sustained fuel reductions, while delivering improved thermal homogeneity and stability.

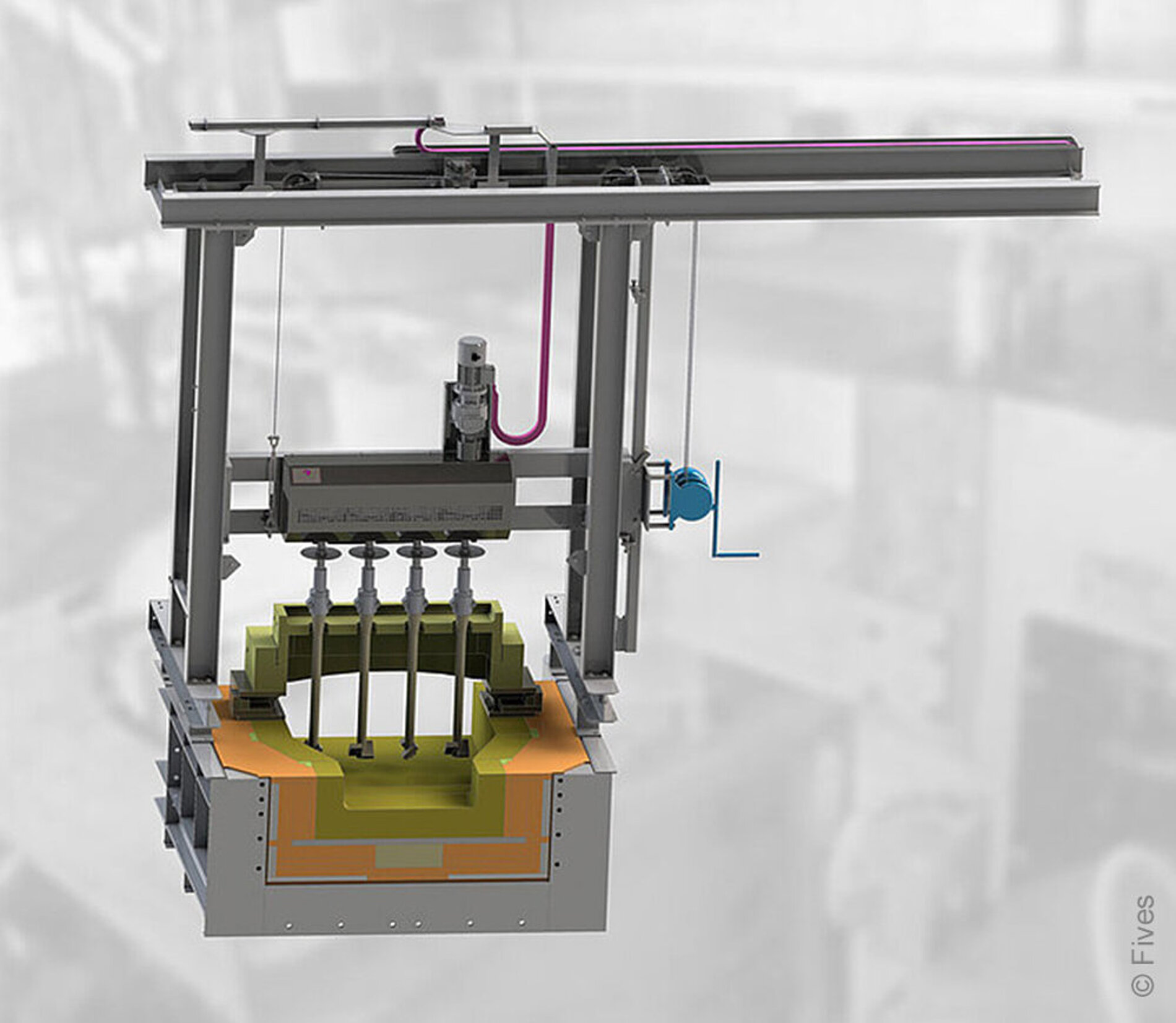

Feeder, stirrer

Long life & easy maintenance

Robust series feeder mechanisms, designed for optimum gob formation. Stirrer mechanisms are available for all forehearth stirring applications and forehearth channel widths.