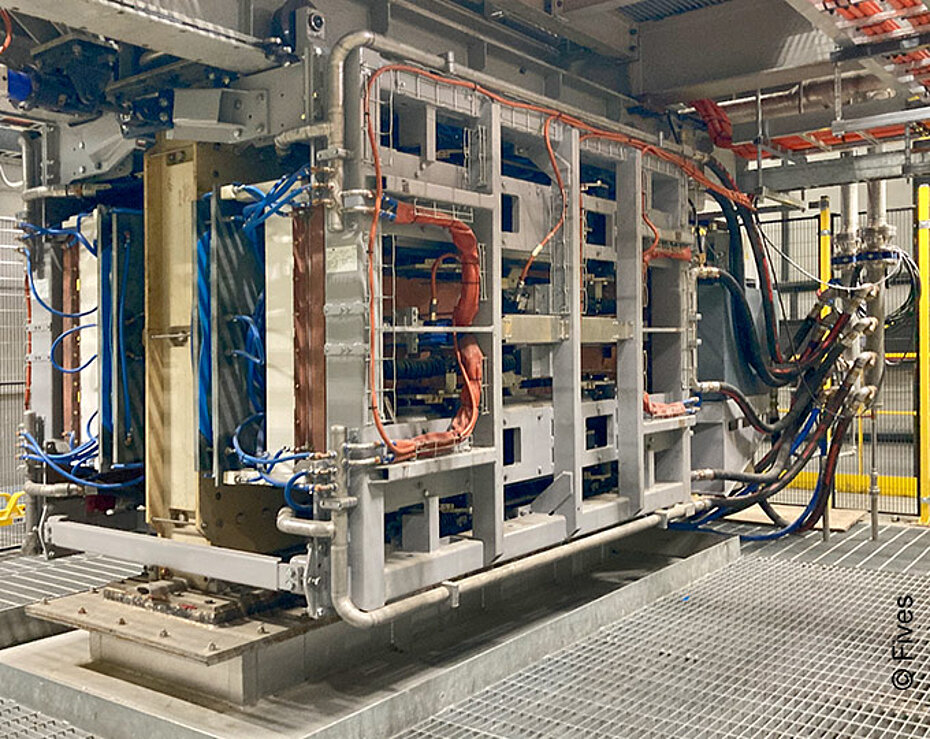

A transverse flux induction heater with very high heating rates at very high temperatures designed for the specific requirements of high-strength carbon, stainless or silicon steel grades. Because it replaces a gas-fired furnace, you can achieve a significant reduction in NOx and CO2 emissions.

Versatile, compact and economical

High-flux induction heating solutions offer an alternative to conventional steel strip heating processes. CELES EcoTransFlux™, transverse flux induction heating technology is a proven alternative for very rapid heating at high temperatures:

- Heating capability: up to 1,200°C

- High heating rates: up to 400°C/sec

- Heating of non-magnetic materials: stainless steel, Gen3 AHSS, etc.

- Thermal efficiency above 75% regardless of strip format

- Compact units for easier integration

- Minimized environmental impact

BREAKTHROUGH DESIGN FOR AUTOMOTIVE STEELS

In order to meet the challenging annealing process of new Gen3 AHSS steels, CELES EcoTransFlux™ - a transverse flux induction heater - is designed for high temperature annealing cycles and galvannealing of steels with a large fraction of austenite.

Benefits:

- Higher temperature increase up to 400°C/s

- High annealing temperatures 900-950°C

- Eco-friendly

Gen3 AHSS features a unique combination of high strength and high formability, which enables new designs of lighter and safer vehicles.

INDUCTION BRIGHT ANNEALING LINE

For energy-efficient bright annealing lines, CELES EcoTransFlux™ can be used to replace a gas-heated furnace. This cutting-edge technology delivers:

- Increased production rates thanks to high energy density

- Excellent energy efficiency

- Reduced environmental impact

- Compact design