Take performance to the limit by eliminating bottlenecks and identifying faults early. Our range of cycle time and process improvement services supports maximum productivity to improve your bottom line.

Avoid programming errors with digital twin

Fives' digital twin allows you to visualize a 3D model of your machine movements to view performance in the past, present or future. Get a clear view of the process in real time during the machining cycle or simulate untested cycles in advance. The digital twin can also replay historical cycles from log files.

In addition, you can test new process cycles for programming errors and cycle time analysis.

Shorten cycle times with GrindXelerator

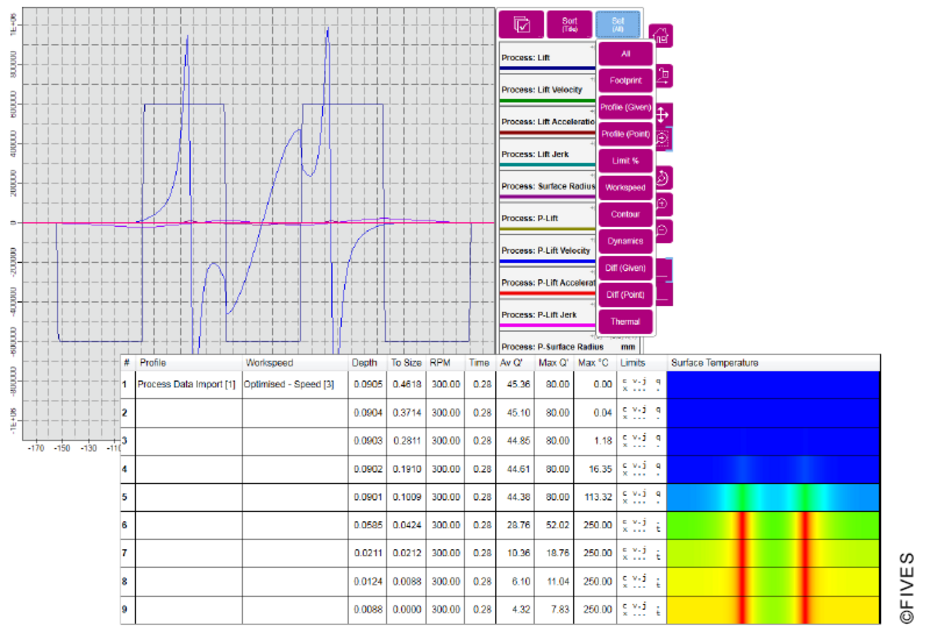

GrindXeleratorTM utilizes the high performance machine capabilities to the optimal level within the constraints of the workpiece and tooling, in order to minimize cycle time while enhancing part quality.

By referring to the kinematics of the machine alongside AI enhanced thermal modeling of the grind process, each revolution of the workpiece is analyzed in order to automatically generate the optimal feeds and speeds.

View a case study on GrindXeleratorTM

Productivity and optimization benefits

Our process and cycle improvement services are a flexible range of solutions that offer an accompanying range of benefits:

-

Reduce cycle times

-

Maximize machine operating parameters

-

Speed-up fault isolation and analysis

-

Visualize changes in performance over time

-

Support preventive maintenance

-

Increase machine availability

-

Enhance productivity

optimize and troubleshoot with logviewer

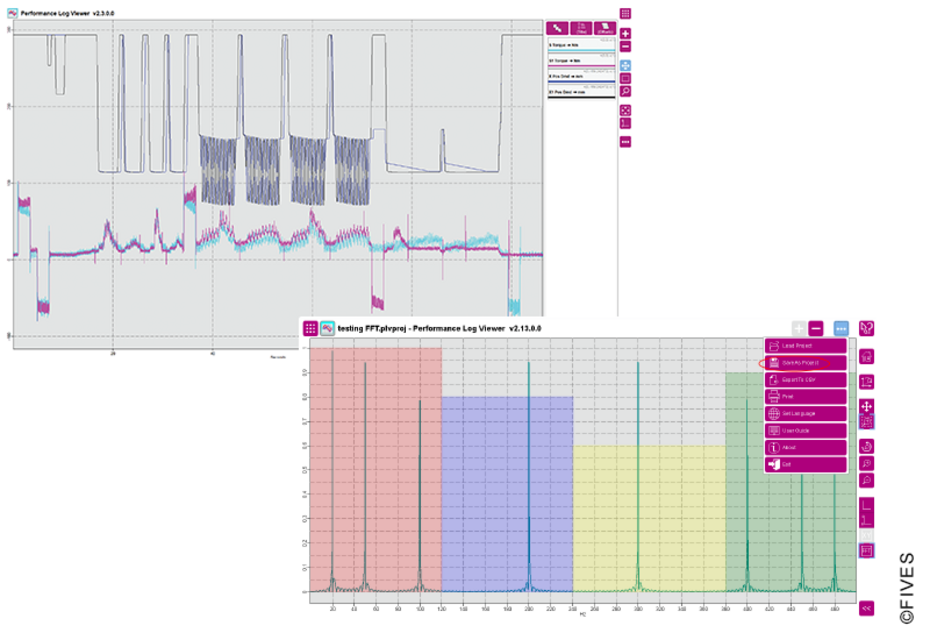

Interrogate your machining cycle by deep diving a wealth of high frequency data to reveal the root cause of problems or opportunties for enhancement. This includes graphical visualizations of time-correlated data such as feed profile vs spindle power in order to adjust cycle parameters. Advanced features include digital signal processing of harmonics and derivatives to highlight critical performance metrics.

Tracking trends with trend analysis

It’s good to know what your grinding machine is doing at any given moment. But the real value is found in understanding how that particular moment compares to other moments. Is it running slower or hotter? Trend analysis (powered by CortX Alchemy) helps identify any changes or deterioration in grinding performance and alerts you to potential problems before they cause major disruption.

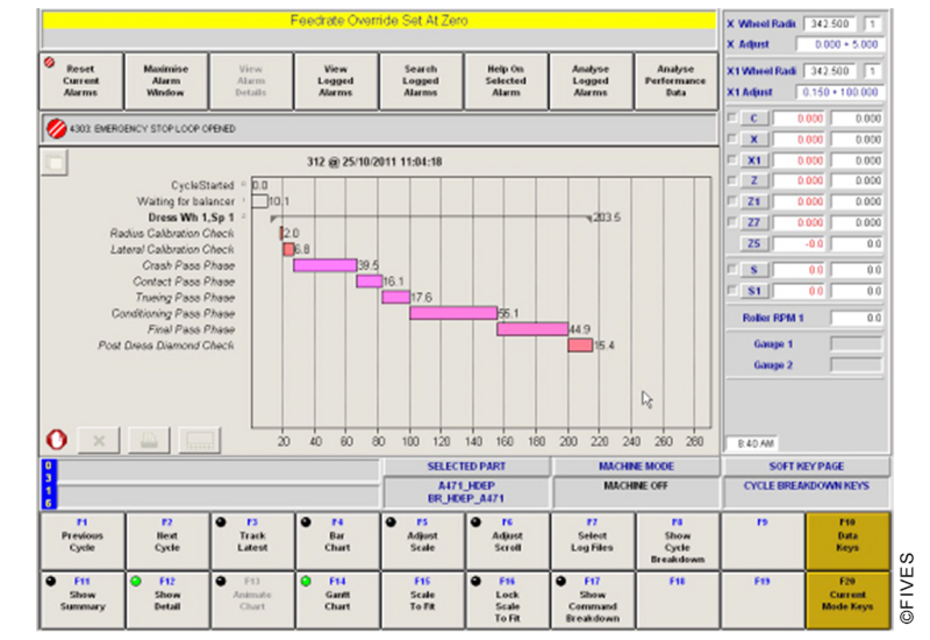

LiveLog

Ever wondered how time is spent in a particular cycle? Our LiveLog software creates a Gantt chart of the cycle that shows exactly how long each element takes. In doing so, you can see where time is lost or (gained) and where there are opportunities for further enhancement.