Fives provides a comprehensive tin bath solution, encompassing every necessary component. Beyond design and construction, this also involves the integration of intelligent equipment to improve the overall efficiency of the tin bath, such as tweel mechanisms, head & end coolers, top rollers, periscopes, tin coolers, pushers, fences, flags.

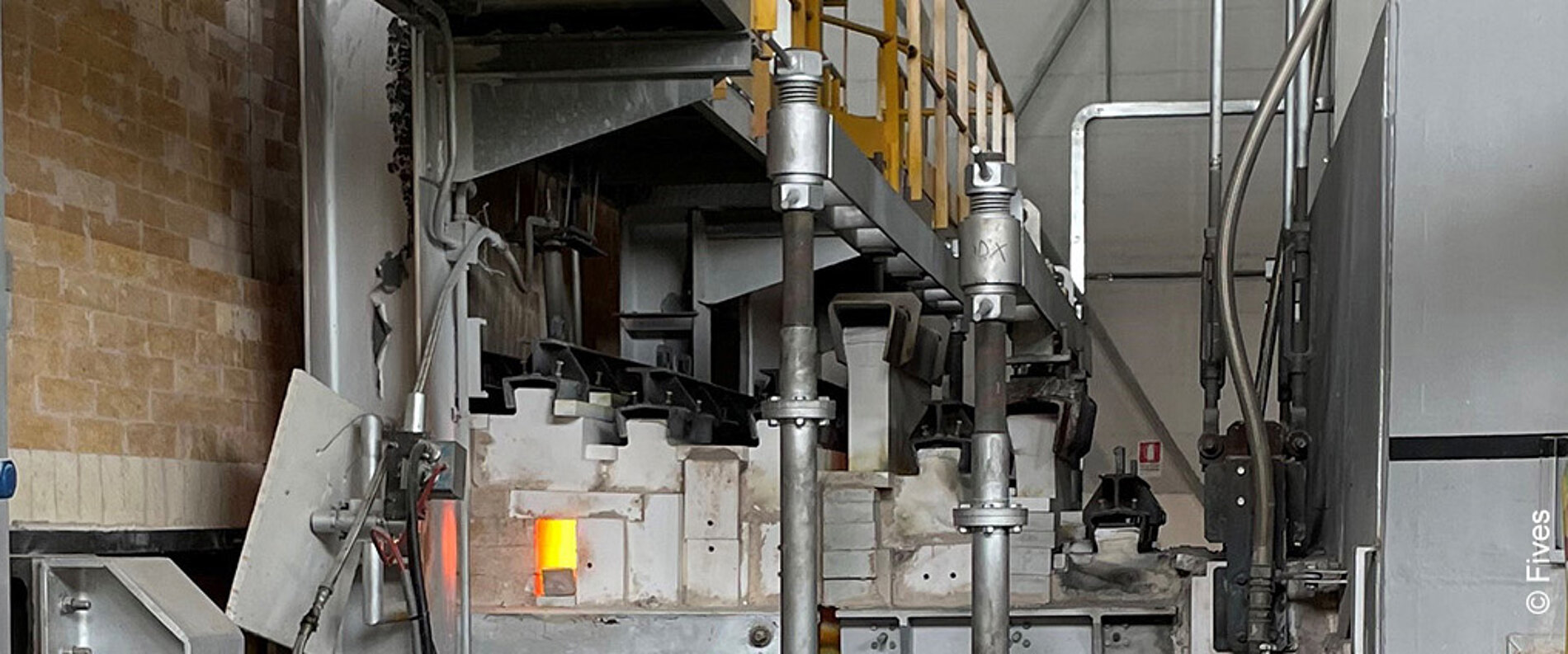

Tweel mechanism

Tweel plays controls the flow of glass melt from the furnace to the tin bath. Motorized tweel ensures precision and performance.

COOLERS

Tin bath coolers control the temperature of the glass ribbon or tin. Removing heat via radiation or convection with submerged coolers.

TOP ROLLERS

Top rollers operate to control thickness and the glass ribbon's width. Various top rollers, ensuring a smooth production process.

PUSHER - FENCE - FLAG

Machines like fences, pushers and flags impact production by keeping the glass ribbon smooth, stable and control currents in the tin bath.

DrossBoX

Designed for maintaining good sealing throughout thermal expansion, reducing counter flow of outer atmosphere, and for adjusting the glass curve, from the tin bath to the annealing lehr.