Pollutant emission control

Fives meets its clients’ needs for strong operational and environmental performance. We support our industry partners through innovative technologies designed to reduce pollutant emissions.

Ground-breaking emissions reduction solutions for eco-friendly operations

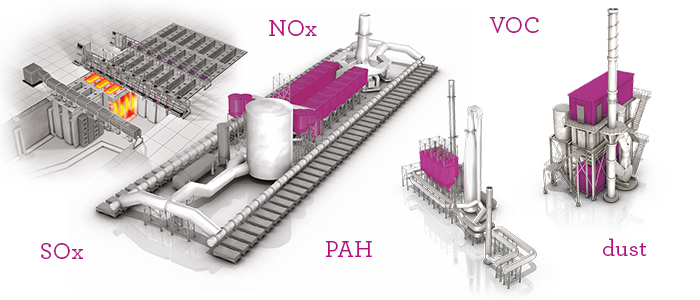

Aluminium producers must continually reduce their stack and fugitive emissions levels to meet stringent environmental regulations.This includes treating pollutants such as HF, NOx, SOx, polycyclic aromatic hydrocarbons (PAHs), volatile organic compounds (VOCs) and dust.

Fives’ gas cleaning processes include:

- Gas Treatment Center (GTC): Treats pollutants emitted by electrolysis pots, via the adsorption process of fluorine and sulfur dioxide by alumina and recycles the resulting enriched alumina into pots to produce aluminium.

- Yprios (or S-Yprios) technology: Reduces fugitive HF emissions inside potrooms by increasing pots suction when hoods are open through:

- Flag dampers at pot outlets connected to a dual duct network (normal & over suction) and booster fans (YPRIOS),

- Dual position diaphragm orifices installed in the single duct nework at pot outlets (S-YPRIOS). - Anode Inert Tray: Eliminates HF emissions from hot spent anodes. The system quickly isolates spent anode butts and is easy to operate, while maintaining low CAPEX and OPEX.

- Fume Treatment Center (FTC): Offers high-end treatment of all pollutants (PAHs, benzo[a]pyrene, HF, tars, dust, etc.) emitted by anode baking furnaces.

- Pitch Fume Treatment System (PFTS): A practical and low-cost solution for absorbing pitch fumes, Fives’ PFTS is available in two versions:

- For Green Anode Plants, the PFTS consists of Eolios, featuring a dry scrubber and a small Regenerative Thermal Oxidiser (RTO).

- For Liquid Pitch Marine Terminals, the PFTS consists of Lineos, featuring a condenser and a Recuperative Catalytic Oxidiser (RCO). - Firing Control System (FCS): Achieves consistent baking levels, low fuel consumption and reduced PAH emissions, thanks to its low-NOx Injectors and advanced control modules.

- Continuous Emission Monitoring System (CEMS): Monitors and controls fugitive HF emissions inside the potroom as well as stack emissions at the GTC outlet, through various sensors and infrared-light analyzers. The system offers operators a complete view of the smelter, helping them perform necessary optimizations to reduce emissions