Fives becomes a member of ACC (Advanced Composites Consortium) to support NASA’s HiCAM project

The HiCAM project addresses an aviation industry need to speed up the production of composites aircraft for meeting the increasing global demand for lightweight transport aircraft.

The consortium is made of 22 organizations (U.S. industry, academia and regulators) which are collaborating to increase the manufacturing rate for aircraft components made from composite (nonmetallic) materials. The project aims to demonstrate manufacturing technologies that enable industry to produce 80 composite commercial aircraft a month, while reducing costs, and improving performance.

Members all have significant expertise in aircraft design, manufacturing, certification, testing and tool development.

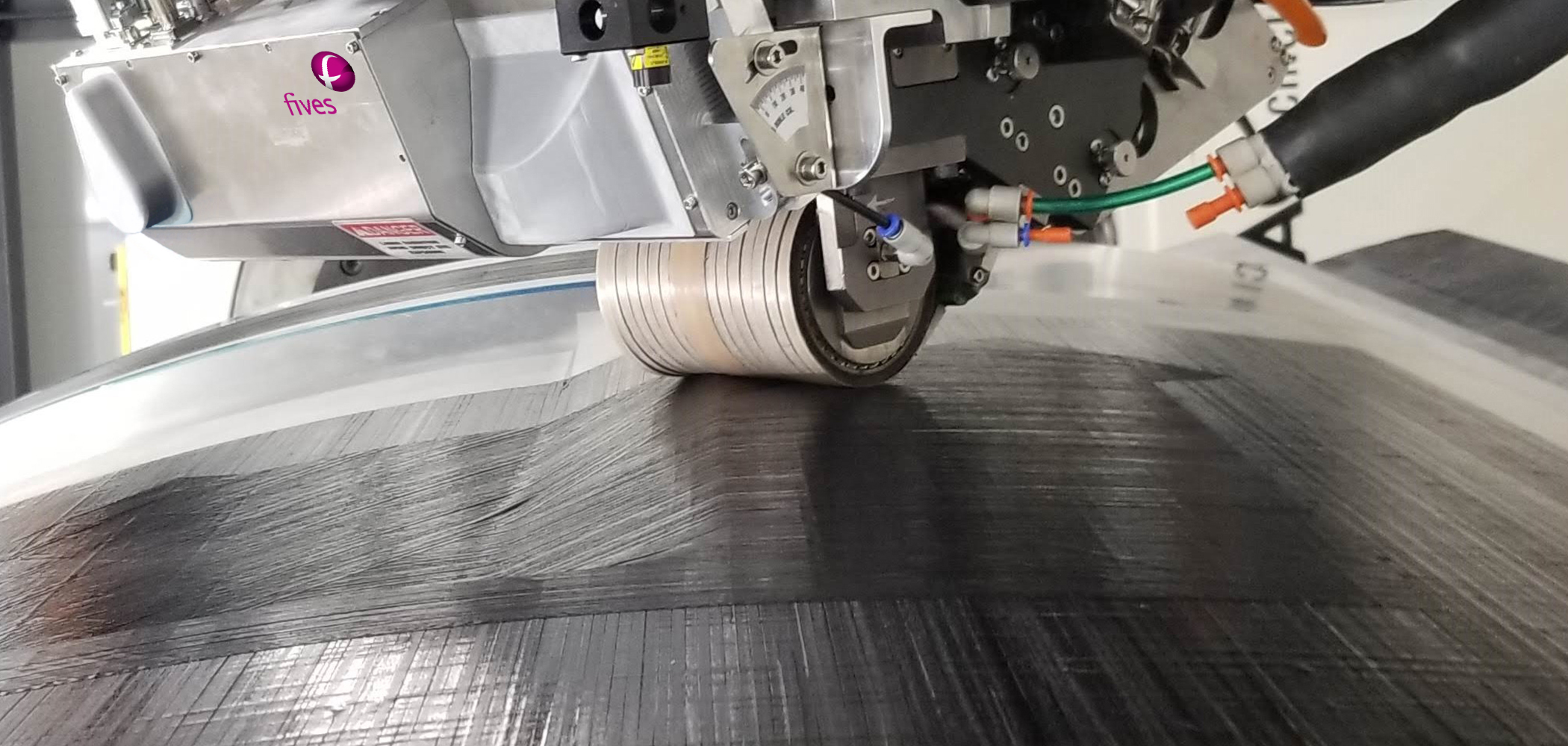

By joining ACC as a new member, Fives will bring important new insights and capabilities, including Automated Fiber Placement (AFP) and Automated Tape Placement (ATP) systems, In-Process Inspection of AFP and ATP, industrialization of aircraft stringer forming, automated solutions already used in the automotive market, and CortX digital/industrial gateway to get value out of machine production to improve part quality and part throughput.

“We are delighted that the Advanced Composites Consortium (ACC) Executive Steering Committee (ESC) has approved our membership and has qualified Fives as a Tier 2 member of the ACC” says John Russell, Vice President of Business Development for Defense at Fives. “Our mission is to bring the Fives Group capabilities from across the companies to help NASA and the industry team not only to meet the growing demand for air travel, replace aging airliners, and secure U.S. competitiveness in the commercial aircraft industry, but also to contribute to NASA’s Sustainable Flight National Partnership by enabling a broader use of lightweight composite airframes, which will reduce fuel consumption and carbon emissions”.