In-Stock High Precision Machines

Fives' High Precision Machines Division offers comprehensive solutions for industries such as aerospace, defense, agriculture, and more. Together with renowned brands Cincinnati, Giddings & Lewis, Liné Machines, Forest-Liné, and Landis, we're your trusted single source for all machining requirements.

Cincinnati - Maxim 630

Large capacity, versatile horizontal machining center

- Rapid traverse of 48 m/min on X/Y/Z

- 2 pallet, one to one swing type APC

- Large part capacity, up to 1000 mm diameter and 1200 kg load capacity

- High power, high torque during low speeds

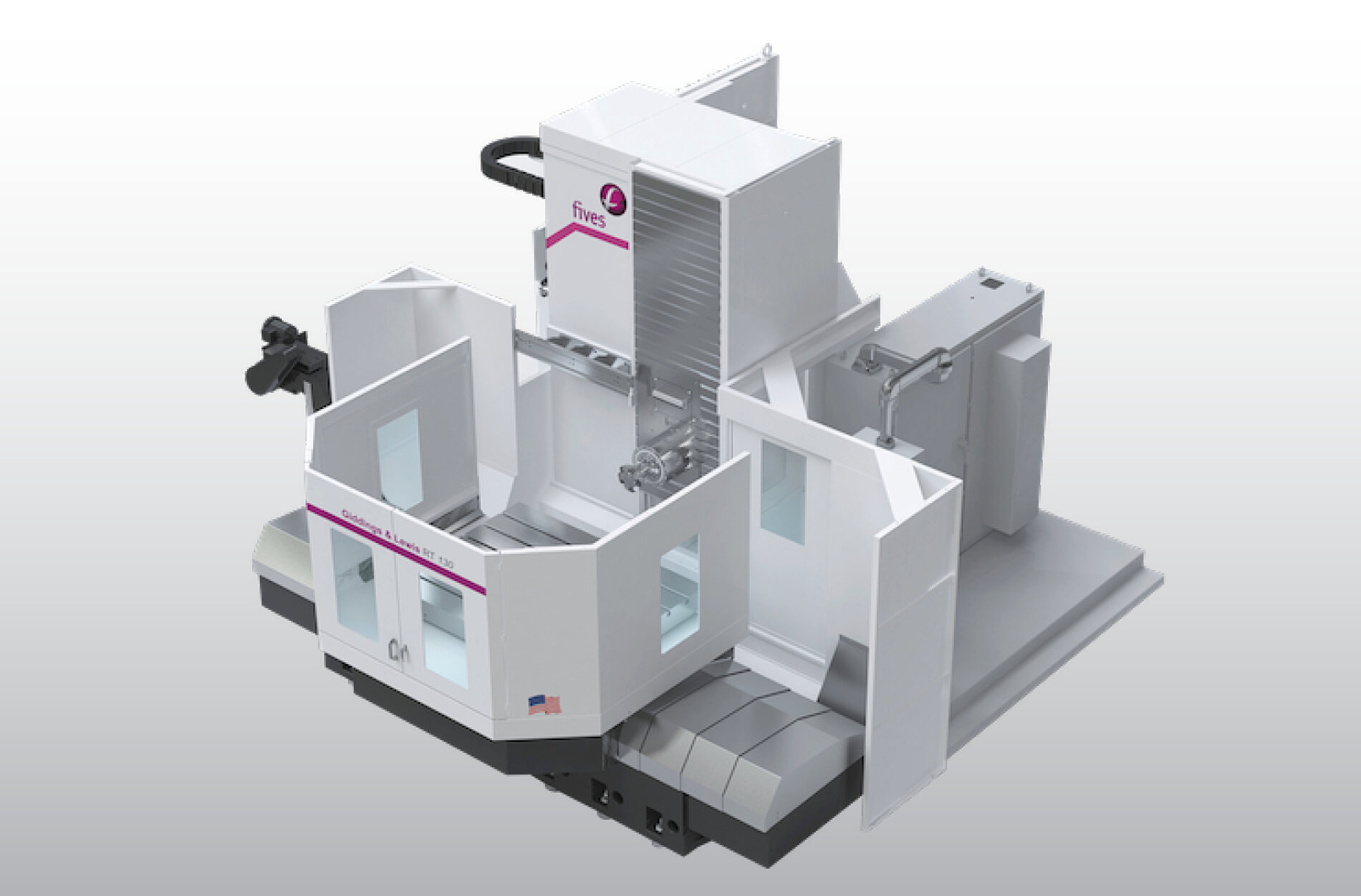

Giddings & Lewis - RT 130

Cross-braced column adds torsional stiffness. Cast iron construction for rigidity. Flat floor foundation. Optional table enclosure, splash shields shown.

- Rotary table size 1250 x 1400 mm

- 12-month warranty

- 40-position tool changer

Forest-Liné - Aerostar

The high-speed 5-Axis Horizontal Machining provides the perfect solution for rapidly removing large volumes of material, such as aluminum alloys.

- Max load 4 tons

- Pallet size 2 x 4 m

- Cast iron or steel weldment

Liné Machines - Powermill V

5 axis large machining center for complex part processing, built for milling, drilling, boring & tapping.

- X 14.5 m (570 in) / Y 4.2 m (165 in)/ Z 1.9 m (74 in)

- Exclusive HS5 head

- CNC: Siemens 840D SL

- Thermal compensation on all linear axis

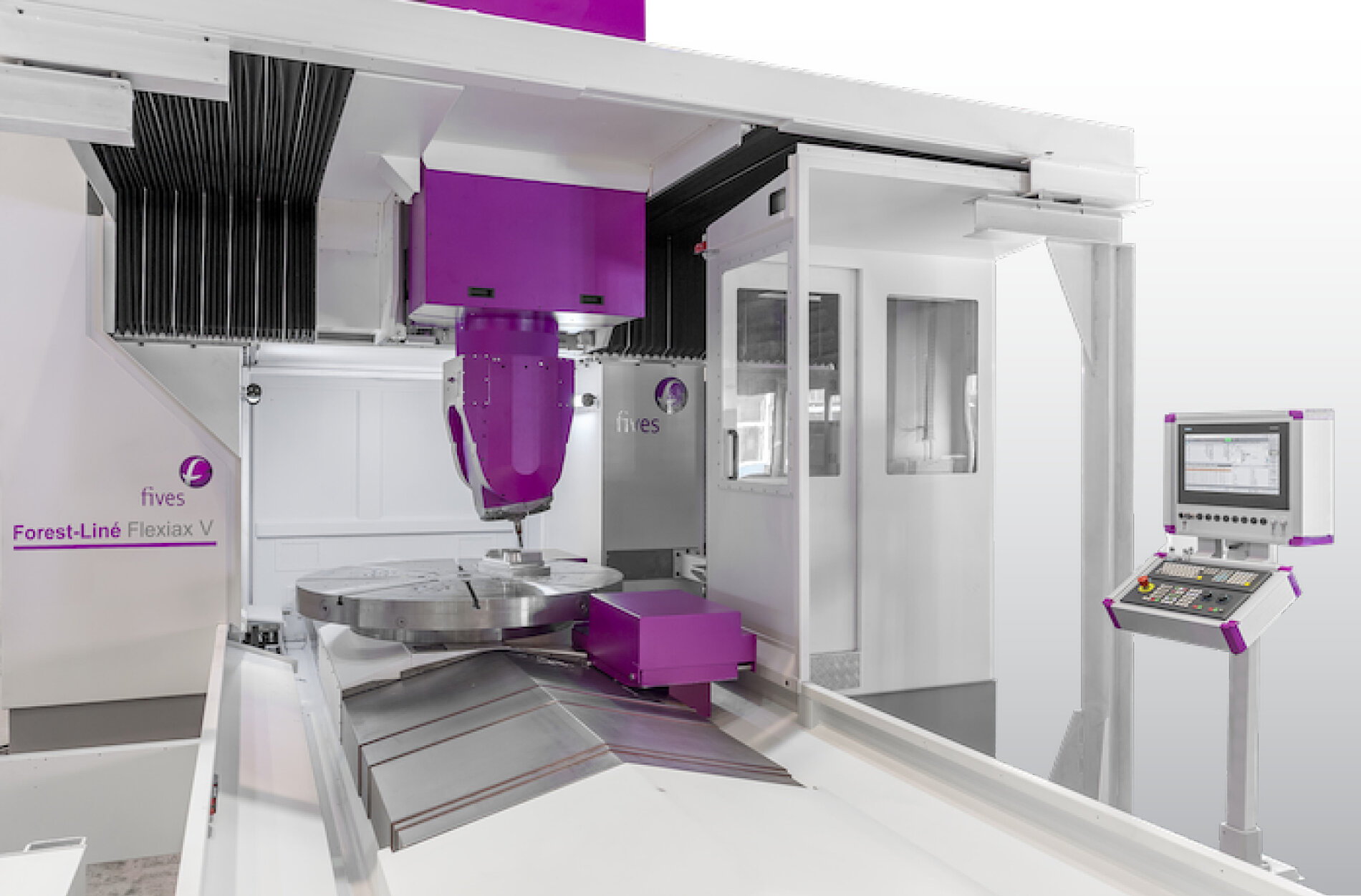

Forest-Liné - Flexiax V

Engineered to ensure exceptional stiffness and stability, this machine delivers the highest possible throughput, while insuring a high degree of accuracy.

- Power 105 kW

- Torque 1 000 Nm

- Speed 10 000 rpm

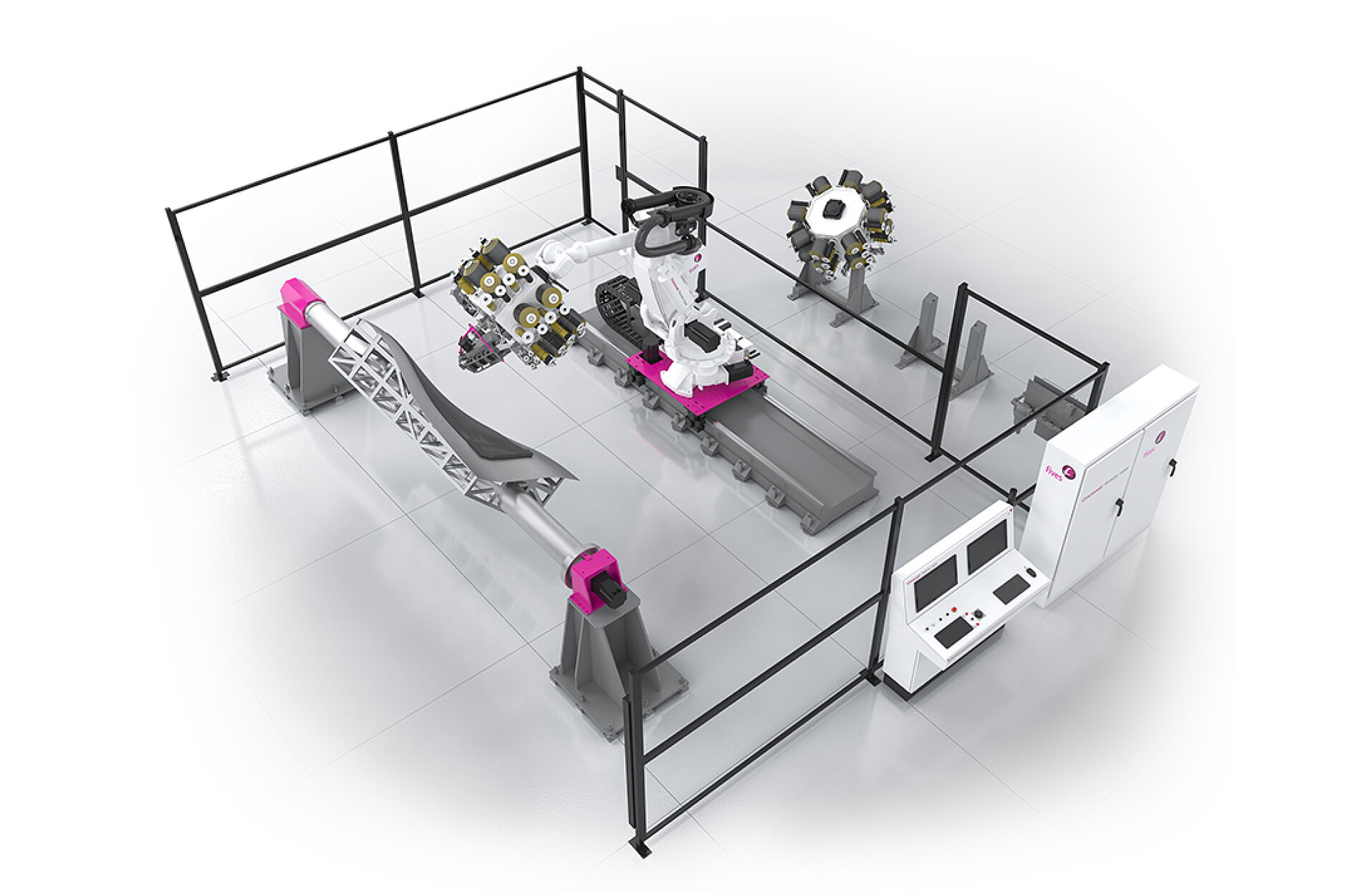

Cincinnati - Robotic Viper

The next generation of automated fiber placement, offered at a lower price point without sacrificing quality, accuracy and reliability.

- Width - 3.2mm, 6.4mm, 12.7mm

- Fixed and docking creel designs

- Tow feed/CCR - add 1.0 m/sec on the fly

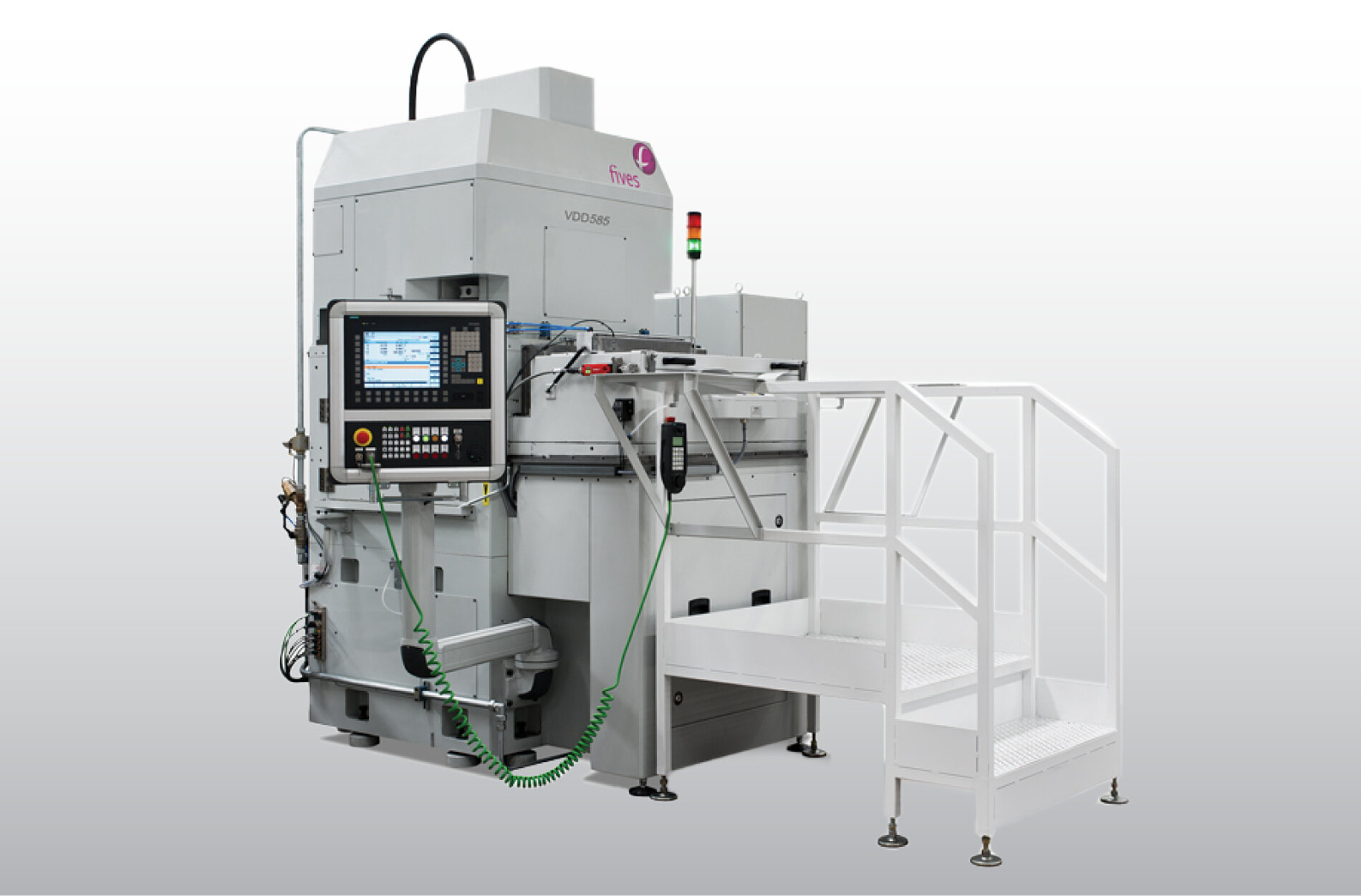

Gardner - VDD 585

Designed for flat and parallel surface grinding. High productivity machine with 3 block cast iron box type framing structure for superior rigidity.

- Max. thickness - 85mm (3.4”)

- Min. thickness - 0.5mm (0.02”)

- Max. power grinding wheel - 22 - 30 kW

Cincinnati - Arrow

The most versatile vertical machining solution. Lower price point without sacrificing the quality, accuracy and reliability.

- Options and capabilities for diverse needs

- Rapid feed rate 48/48/36 mm

- Spindle speed 10000 rpm

Landis-Bryant - RU1

Designed for bearings, automotive, fuel management, valve & drive train applications & other high precision applications for various industries.

- Max. swing diameter - 127mm

- Max. workpiece length - 63mm

- Max. internal grinding diameter - 38mm

Giddings & Lewis - V 1250

Cast iron cross-braced contruction. Large ram cross section adds rigidity for heavy cuts. Table sizes 800 - 1600 mm. Tool and part probes available.

- 1250 mm plain table with boring mill jaws

- Installation and 12-month warranty

- 20-position tool changer

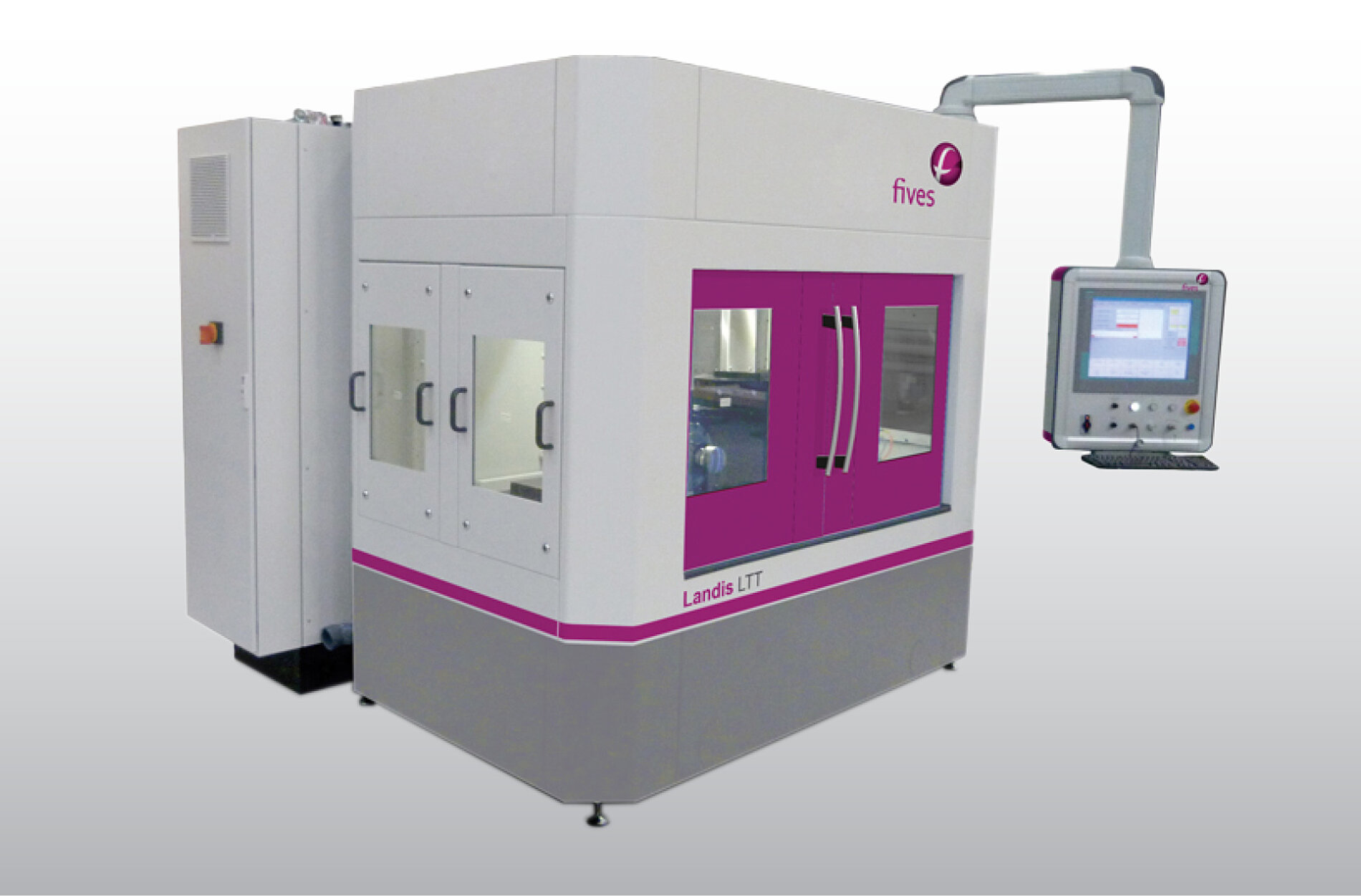

Landis - LTT

Twin-turret, multi-spindle solution to grind ODs, IDs, faces, tapers, concentric and eccentric diameters to sub-micron tolerances in single clamping.

- Max. grinding diameter (OD) - 100mm

- Max. external grinding length - 100mm

- Min. internal grinding length - up to 100mm