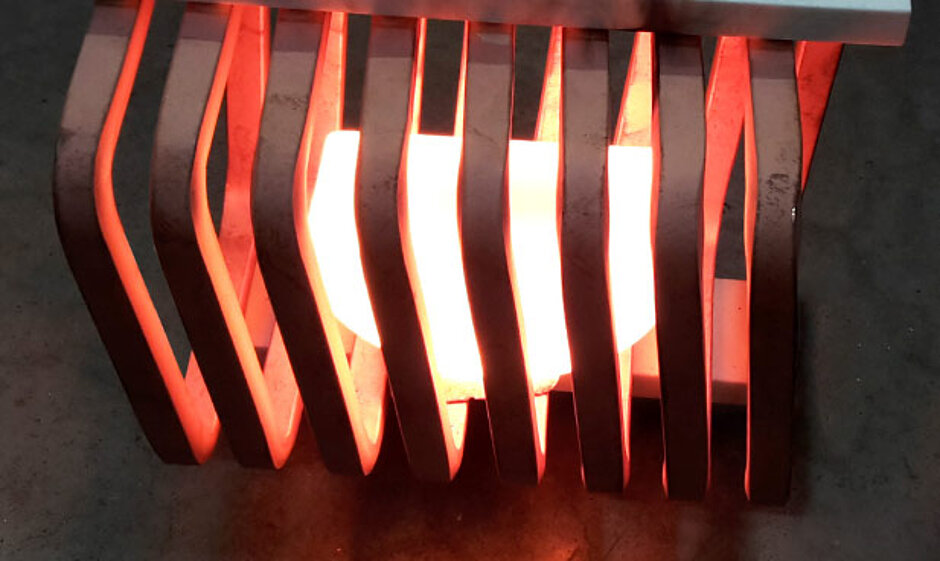

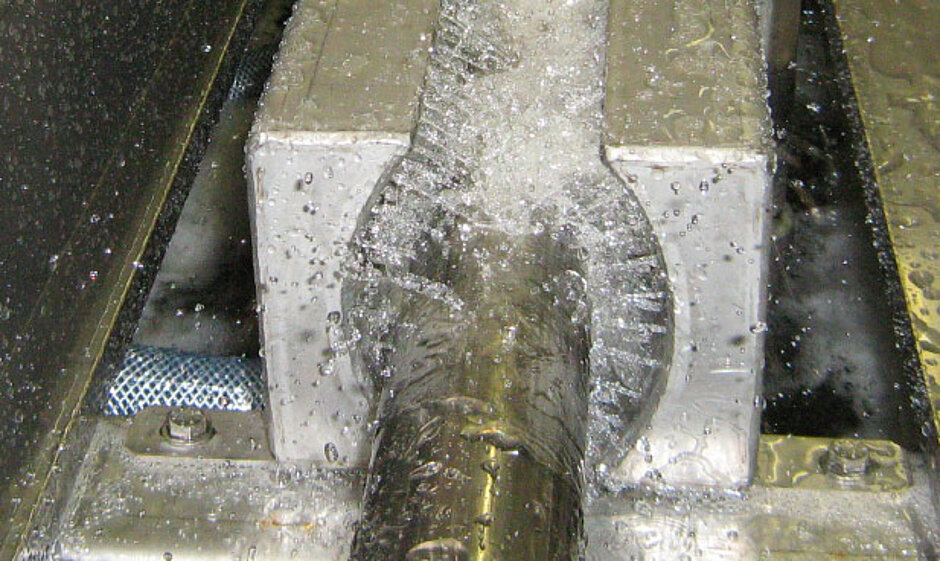

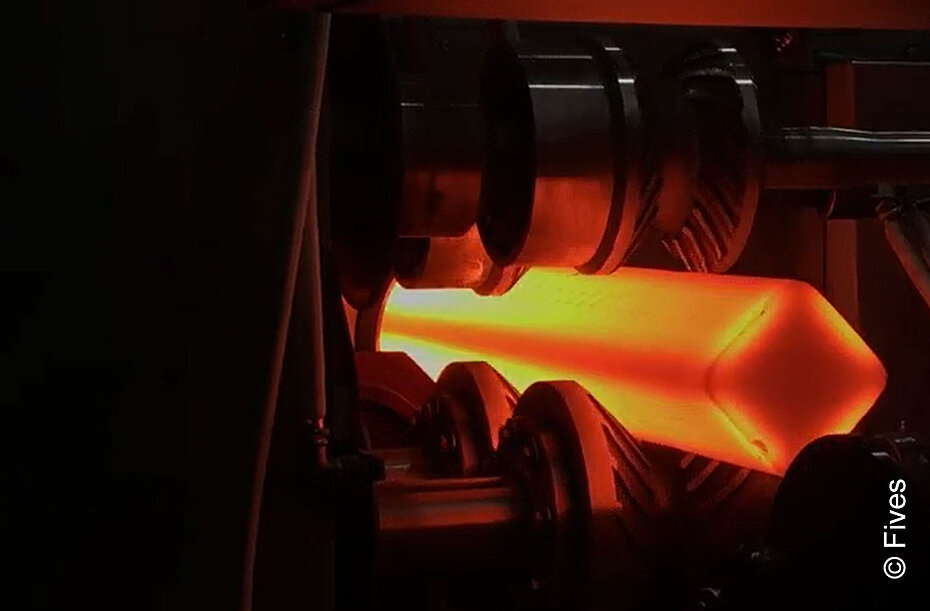

Drawing on decades of experience, our induction forging systems deliver high performance and efficiency through absolute control of the heating process. This allows heating of billets, slugs, bars, tubes or rails before the rolling, reducing or tapering processes to increase productivity.

HIGH ENERGY EFFICIENCY

Induction forging is a simple, fast and efficient way to heat metals prior to forming.

Heat can be applied specifically to the parts of the metal being shaped. This allows not only much greater control, but also increased efficiency.

No energy is wasted heating parts that don’t need forming. And, likewise, the metal that is not being shaped is left alone. This ensures there is no loss of integrity, which could reduce the metal’s quality or performance.

High productivity

Another advantage of induction forging over a conventional furnace is the speed at which the metal is heated. This enables much higher productivity, whether you choose static or line heating for your application.

Depending on your requirements, we offer a range of manual or automated solutions:

- Static or line heating with a solenoid or tunnel inductor

- Passage heating in high efficiency inductors

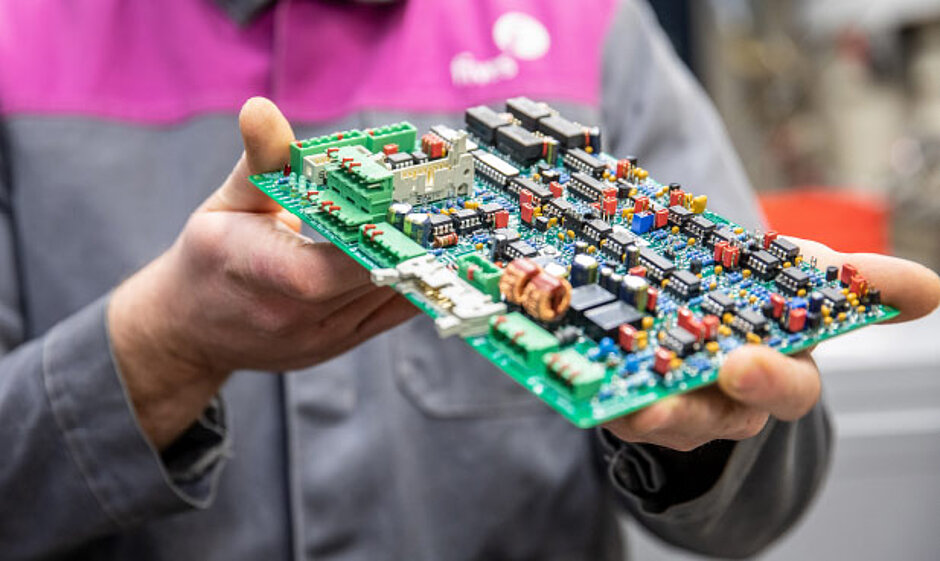

Our power converters are designed with very wide impedance ranges enabling heat continuity to be maintained, even beyond the Curie point.