Control systems

Cutting-edge combustion control for a range of applications

Our high-tech control systems monitor and adjust every step of the combustion process. We offer burner management and combustion management systems as well as electrical cabinets for a range of applications and industries.

Fives’ innovative and high-tech solutions are easy to install and can be customized to suit various safety requirements and other customer specifications.

Advanced control panels for process heating, petrochemical equipment and revamping

Our ITAS control panels are used in a range of industries and applications. They are also ideal for specific petrochemical equipment and/or revamping of equipment such as incinerators, thermal oxidizers and fume treatment units. Compatible with diverse end-user requirements, these panels remove the need for several control components (for example, programmable logic controllers (PLCs)), saving time and cost.

ITAS control panels integrate the best burner control units (BCUs) available on the market. BCUs ensure safe start-up, operations and shutdown. It also integrates the combustion control system for proper fuel and air flows. These solutions are both reliable and flexible, and can be customized according to any client’s needs.

State-of-the-art thermal process control for aluminum, steel, paper industries and more

Our North American Safety PLC-based process controls integrate burner management logic (BMS) and control management logic (CMS), enabling our clients to make better process management decisions. Easily integrated into companies’ industrial internet of things (IIoT) and Industry 4.0 ambitions, our panels offer:

- Reduced unplanned furnace downtime

- Optimized fuel use

- Decreased emissions & waste

- Proactive maintenance

- Process insights & data to customer network

These solutions are built around Safety PLC systems, providing maximum flexibility for innovative customers. They are used in a range of applications, including aluminum melting, steel reheating, forging, heat treatment, iron ore pelletizing, tissue paper manufacturing and more. We also offer Level 2 Automation, a solution that facilitates material scheduling, tracking, documentation, heat modeling and handling of manufacturing processes in a range of applications.

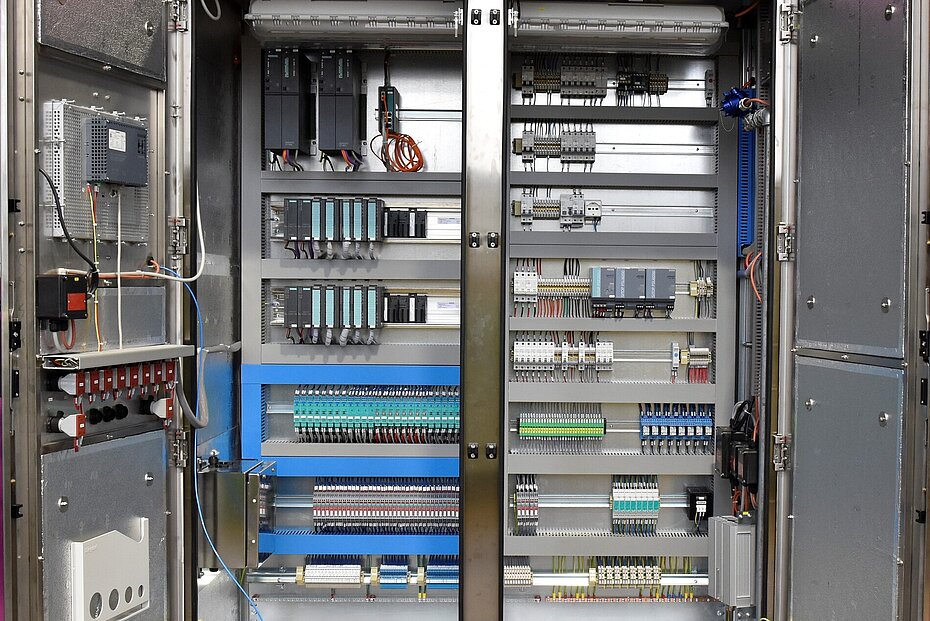

Tailor-made electrical cabinets and combustion control for all industries and applications

Our tailor-made solutions includes Pillard electrical cabinets, BMS, CMS, burner control panels (BCP) and combustion control systems (CCS). These Pillard Control Systems cover both multi-fuel and single or multi-burner applications, and are based on our Run-Safe concept, which enables simultaneous safety and availability control. Built on a certified and proven software package, the systems are easy to maintain, which further reduces cost and downtime.

We offer standard electrical cabinets or can deliver cabinets that are specifically designed to comply with various certifications and concerns, including:

- EEC (EN746-2, EN298...) and ISO standards

- NFPA 85 and 86 codes

- ATEX directive or National Electrical Manufacturers’ Association (NEMA) compliance

- Safety Integrity Level (SIL)

- Underwriter Laboratories (UL)

- FM Global

- Eurasian Conformity (EAC)

Product Finder

Find the combustion solution that fits your needs

Browse and download our related product literature