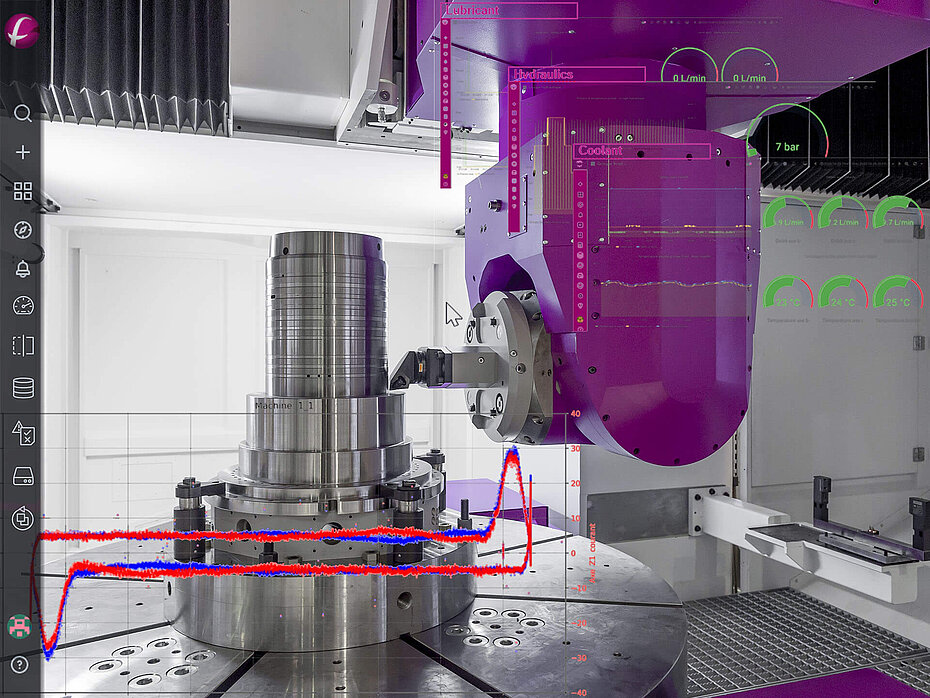

The predictive failure diagnosis and prognosis models that we develop for a system and its sub-assemblies allow for advanced monitoring of the health of production equipment through the analysis of vibrations and other analog signals.

PREDICTIVE MAINTENANCE ON 5 AXIS MACHINE TOOLS

Defense sector

A solution developed in collaboration with Fives' Maintenance and Metal Cuting | Composite teams.

Objectives:

- Increase the availability of machines.

- No longer suffer from downtime and plan maintenance according to actual anticipated needs.

- Validate the deployment plan on other means.

The Solution:

- Targeted instrumentation, based on a FMEA to increase the observability of critical defects.

- Real-time access to data and alerts to monitor the condition of the machine.

- Machine located indicators for operator control.

- Intelligent vibration diagnostics based on the machine's operating conditions.

- Early diagnosis and localization of axis faults based on continuous analysis of drive data: Gantry alignment, friction or hard points, reversal error.

- Predictive model on the most critical subsystems of the machine.

Benefits:

- After a few months of operation, already 3 major defects anticipated and corrected outside of machine opening times.