Our experts capitalize on the know-how of the Fives group and jointly develop embedded solutions natively in the equipment to perform real-time analysis.

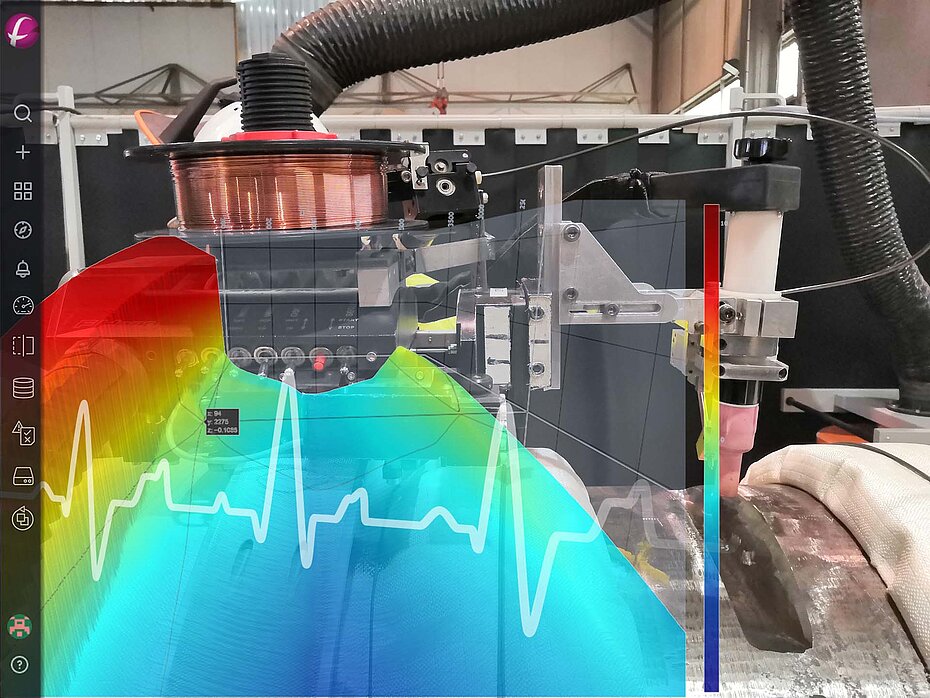

ORBITAL WELDING

Nuclear sector - orbital welding.

Objectives:

- Minimize delays due to late detected weld non-conformities. Get it right the first time.

- To produce the highest quality orbital weld in the industry.

The Solution:

- Develop a complete vision system through our CortX Alchemy platform to:

- Digitize paper-based processes and gain traceability.

- Check weld geometries, as early as possible, with 3D laser measurement in order to prevent high risk defect areas.

- Synchronize information from several data sources (MES, suppliers, etc.) and automate report generation.

- Ensure weld quality by tracking weld parameters in real time and alerting the operator during poor conditions.

Benefits :

- Real-time monitoring of weld quality allowing complete traceability of the process and early identification of non-quality.

- Make possible advanced treatments to determine the root causes of non-quality and predict defects... on a process that was still manual 12 months ago.

STUDY OF THE INSTALLED BASE

Machine tool manufacturer - After sales service

Objectives :

- Define the actions to be implemented to revitalize after-sales service.

- Contribute to the maintenance and development of spare parts sales activity by analyzing data :

- Identify customers and active machine base.

- Identify the risks of disengagement of certain consumers of spare parts.

- Find business development opportunities.

The Solution:

- Analyze sales history to identify the active installed base, understand the aftermarket, and investigate customer disengagement.

- Analysis of market size and growing geographic areas.

Benefits:

- A list of customers likely to be disengaged, as well as short- and medium-term actions were identified and forwarded to marketing teams for targeted sales actions.