INNOVATION is

DISRUPTION

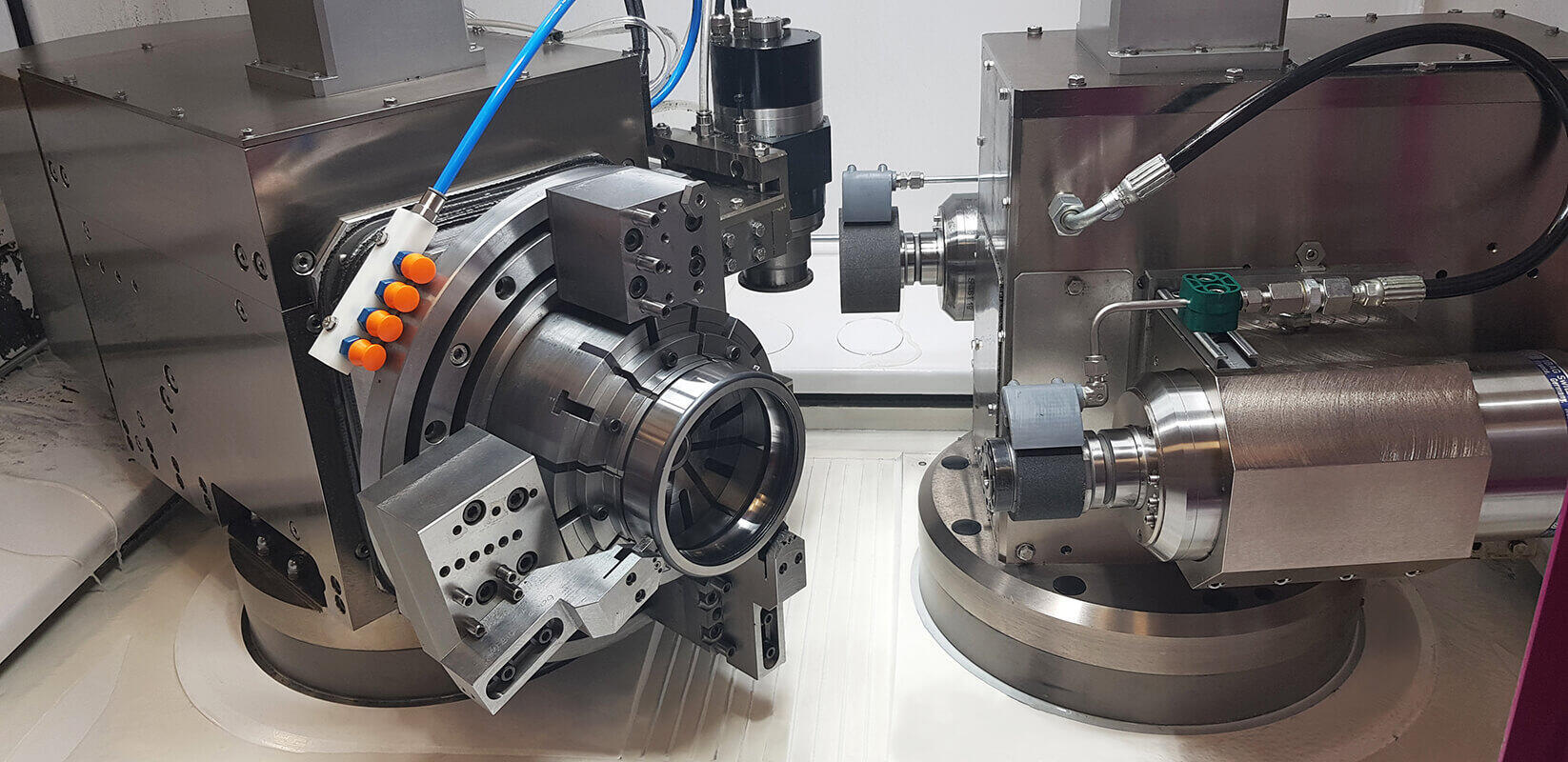

BRYANT TTG, the game changer in the bearing manufacturing industry

Grinding has always been considered one of the least flexible manufacturing processes, with downtimes when a changeover is required.

To address this problem, the Fives Global Product Development teams have adapted the Bryant TTG machine, originally engineered as a high-end optical grinding solution. By combining multiple grinding operations into one single, it allows manufacturers to:

- Produce different types of bearing for various applications, without losing time during production changeovers and without increasing the number of machines;

- INCREASE THEIR PRODUCTION CAPACITY AND REDUCE THEIR OPERATING COSTS;

- QUICKLY REACT TO MARKET DEMANDS, WITHOUT SACRIFICING ACCURACY.

The Bryant TTG can grind outside and inside diameters, faces, tapers, concentric and eccentric diameters, every feature of a bearing, up to 320 mm in diameter.