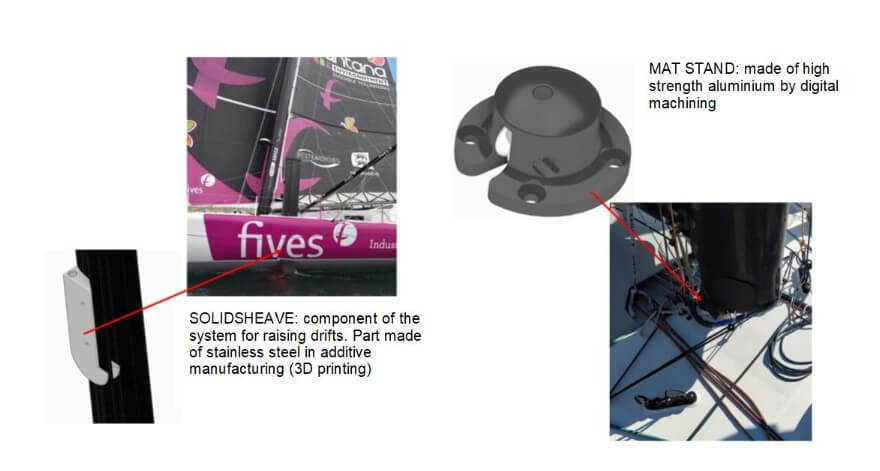

AddUp, a subsidiary of the Fives group, has manufactured solid sheaves, parts of the system that allows the IMOCA Fives Group – Lantana Environnement to lift and lower its drifts using metal additive manufacturing.

Powder bed fusion is a cutting-edge 3D printing technologyused in healthcare, aeronautics, aerospace sectors among others.

AddUp, a designer of metal additive manufacturing machines, has been a key player in this metallic 3D printing for more than 20 years and it was a pleasure for the AddUp team to put its expertise at the service of skipper Fives Group – Lantana Environnement!

Short lead times

Maxime Pyzak, AddUp project manager: “Louis Duc’s team urgently needed these parts: additive manufacturing allows very short production times. That’s one of his big advantages when compared to traditional manufacturing.”

It took only 20 hours of production to make the solid sheaves and 3 hours of finishing, by hand, to perfectly smooth the surfaces.

We deposit and fuse together layers of metal powder

“We use laser fusion technology on a powder bed: we deposit a layer of metal powder of a certain thickness, in this case it was 40µm. Then, a laser fuses the material, then we deposit a new layer of powder and so on, in successive layers, we get the object in 3D.

Additive manufacturing is used for parts of very complex shapes and/or for very short lead times.”

Anticipation is key

“From a 3D file we orient the part in order to limit the support structures. The optimization of support structures reduces the manufacturing time and the final cost of the part. This is a key aspect of additive manufacturing.

The laser strategy then needs to be determined: define laser speed, power, and distance between 2 laser paths, etc. This is again a complex step

For the IMOCA parts, made of 316L stainless steel at their request, we have, with the team of Louis, slightly adapted their design so as to make it compatible with additive manufacturing. We then defined the laser strategy and the right support structures.”

“Fives Group has been with me since 2005. It is a meaningful partnership based on values and a common ambition: innovation, performance, team spirit… They are the driving force behind our commitment to a more sustainable world” Louis Duc, Skipper

AddUp, designer of metal additive manufacturing machines for all needs

The result of more than 20 years of experience in metal additive manufacturing, AddUp machines have been designed to manufacture high-precision parts while optimizing productivity. Reliable, repeatable and industrial, they are designed for mass production. Fully integrated into a digital environment, they allow you to solve your most complex challenges in an innovative way.

A respectuous and circular sporting event

The Fives IMOCA is an "upcycled" boat. Thanks to Louis, it lives a 2nd life!

Louis and his team gave a new life to a very damaged IMOCA because of a fire. This refurbishment undertaking was a real technical challenge... that succeeded in only 10 months!

Louis and his team continue to apply this upcycling principle and optimization research with a constant effort on sobriety throughout this Vendée Globe program.

Louis is also very keen on respecting everyone's work and giving a chance.

The Fives Group, a major partner in this Vendée Globe program, has been seduced by such commitment and values, as it shares the same values and responsibilities.

Fives, your partner for a more virtuous industry

For over 200 years, the Group has designed the breakthrough solutions and technologies that make industry what it is. From the first railways to the Eiffel Tower, through the spatial conquest, Fives always spearheaded the industry of the future. Pioneering decarbonization, the Group is an unconditional partner of the industry's energy transition. Through digitization, the promotion of a circular economy and the development of new processes and new energy sources, Fives puts its technological leadership to its customers' service.

www.fivesgroup.com